Plastic Injection Molding Service

Offer high/medium/low volume injection molding services. | Capable of molding parts weighing up to 3000g. | Precise molds with tolerances +/- 0.01mm or less | Certifications: ISO 9001:2015 & ISO 14000:2015.

Plastic Injection Molding Service

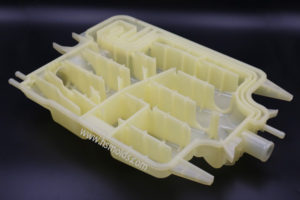

We are the molding company that specializes in precision plastic injection molds and precision plastic parts using a broad selection of engineering materials. We use the latest machines and certified materials to provide plastic injection molding service to customers with outstanding quality, precision, and speed of service.

Our facility contains modern molding equipment We use robotics to produce high volumes at reasonable prices for automation-friendly assemblies. Low volume to high volume, our people and equipment stand ready to design, manufacture, and test high precision parts.

Plastic Injection Molding

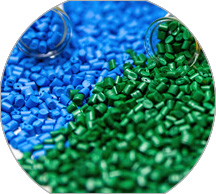

Plastic injection molding is the process of melting plastic pellets that once malleable enough, are injected at pressure into a mold cavity, which fills and solidifies to produce the final product.

Overmolding

Overmolding creates chemically bonded parts from multiple materials, such as covering plastic, metal, and rubber over each other. This process helps reduce assembly time and adds flexibility.

Insert Molding

Insert molding involves the process of molding a plastic part around a different core product, which is often made of metal.

Gas Injection Molding

Gas-assisted molding is a process that forces a short shot of material to fill a mold by using pressurized nitrogen gas to displace the material in a pre-destined thick area while forming hollow sections in the part.

What Kinds of Materials We Use For?

We are an experienced injection molding company, we offer a wide range of certified materials to provide customers with outstanding quality. We can also source any type of commercially available material per our customers' requirements in the appropriate quantity. The materials we often use are: ABS, PA6, PA66, PP, PC, PC/ABS, PS, POM, PPS, and so on. Fiberglass, inorganic fillers, and some pigments will be added to some plastics according to customer requirements.

- Acetal polyoxymethylene (POM)

- Acrylonitrile butadiene styrene (ABS)

- Nylon 66 (PA66)

- Glass-filled, polyamide (PA-GF)

- High-density polyethylene (HDPE)

- Low-density polyethylene (LDPE)

- ABS polycarbonate (PC-ABS)

- Polyethylene terephthalate (PET)

- Polymethyl methacrylate(PMMA)

- Polyphenylene sulfide (PPS)

- Polypropylene (PP)

- Polystyrene (PS)

- Thermoplastic elastomer (TPE

- Thermoplastic vulcanizates (TPV)

- Polycarbonate (PC)

- Polybutylene terephthalate (PBT)

- Polystyrene + polyphenyl ethers (PS-PPE)

- Glass-filled polycarbonate (PC-GF)

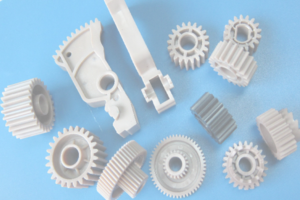

HS plastic molding company has rich knowledge and experience in supporting clients in automobile parts manufacturing, household appliance plastic injection molding, medical parts injection molding, industrial product plastic molding, robotics, consumer products, and other fields of custom molding means you can be confident we have the expertise to meet even the most challenging of production requirements.

Injection Molding Service Industries

- Auto Parts

- Household Appliance

- Industrial Parts

Injection Molding Capabilities

We are a molding company that is capable of producing injection molded parts with weights of up to 3000 g. We have 63 in-house plastic injection molding machines with a capacity ranging from 60 to 700 tons. We offer fast and easy engagement, with consultancy from the start by engineers and project managers with an average of 10+ years of experience.

Equipment List

Size - Maker - Qty

- 60T - HAITIAN - 12 Machines

- 80T - NISSEI - 1 Machine

- 100T - NISSEI/SUMITOMO/FANUC - 5 Machines

- 120T - HAITIAN/TAIFU - 9 Machines

- 130T - SUMITOMO - 2 Machines

- 150T - HAITIAN/WELLTEC - 2 Machines

- 160T - HAITIAN - 13 Machines

- 180T - SUMITOMO - 3 Machines

Size - Maker - Qty

Size - Maker - Qty

- 200T - HAITIAN/WELLTEC - 4 Machines

- 250T - HAITIAN - 3 Machine

- 280T - HAITIAN - 2 Machines

- 300T - HAITIAN - 1 Machine

- 320T - HAITIAN - 2 Machines

- 450T - HAITIAN/JSW - 2 Machines

- 700T - HAITIAN - 1 Machine

Size - Maker - Qty